Testing Machinery

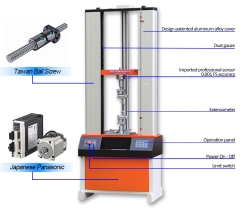

1KN - 20KN Universal Testing Machine SF-1003A

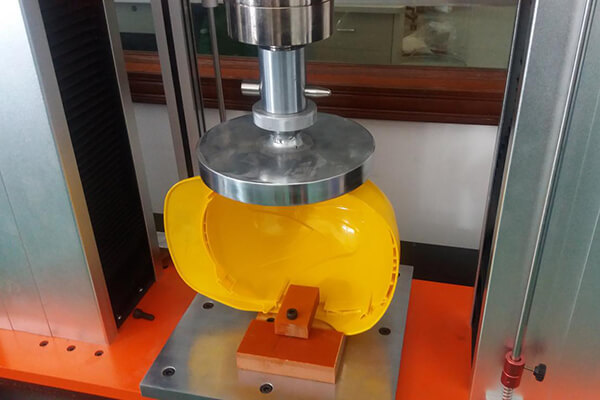

Universal Testing Machine (UTM) SF-1003A is used to test both the tensile and compressive strength of materials. Universal Testing Machines are named as such because they can perform many different varieties of tests on an equally diverse range of materia

$0.00

Description

Equipment Summary

The machine is designed by mechanical-electrical integration, composition of the force-measuring sensor, transmitter, microprocessor, mechanism of load drive, computer and color inkjet printer. High-precision electronic motor can be set to five-speed, the components are connected by plug-way, Floor-standing models, it is taken account of modern industrial design and ergonomics in modeling and coating. It can be tested all the materials in stretch, compression, bending, shear, embedded relay, peeling, tearing, crack, etc, such as rubber, plastics, leather, metal, nylon wire, fabric, paper, aerospace, packaging, construction, petrochemical, electrical, vehicle, etc.

Technical Parameters

| Model | SF-1003A |

| Max load | 20KN |

| Accuracy | 0.5grade |

| Effective force range | 0.4%~100% (0.5grade) |

| Resolution | 1/200000 |

| Load cell | Basic configuration:one piece( max load) |

| Enlarge configuration:can be increased extra laod cell | |

| Effective test width | 390mm (can be enlarge as customer request) |

| Effective Tensile stroke | 800mm (can be enlarge as client request) |

| Test speed | 0.01~500mm/min |

| accuracy of displacement | ≤0.5% |

| Test bench safety device | Electronic-limit protection |

| Test bench lifting device | Fast /slow ( two speeds to control), can jog |

| Overload protection | Overload 10%, automatic protection |

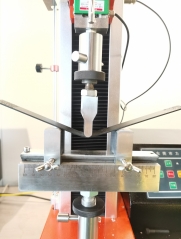

| Fixture | One set of standard tensile grip |

| Dimentions | 870*540*2200mm(L*W*H) |

| Drive system | Taiwan “Delta” AC servo motor +drive+High precision ball screw |

| Power supply | 220V, 50HZ |

| Power | 0.4KW |

| Weight | About 300 Kg |

Specifications:

1.Computer Servo Type Universal Testing MachineA. High-precision sensor 1ton from the U.S.A. Accurate Forces within ± 0.5%.

B. High-precision 24 bits A / D, sampling frequency 200Hz

C. Power System: Panasonic AC Servo Motor + Driver + CAVEX + precision ball screw

D. Control System: it is more precise using Pulse Command control modem, the range in speed control is 0.01 ~ 250 mm / min.the board of iron can be adjusted to fast and slow by the control board. it is automatically saved after testing.

E. Data transmission: RS232 Transfer

F. Display: Windows XP test software.

G. easy to control five-speed and calibration system.

H. test software can precision control in position, speed, rate of load force and rate of stress, satisfy the different requirements of test.

I. Test space: Testing width is about 400 mm (standard), moving space of active iron 1000mm (excluding fixtures)

J. displacement: coder 2500 P / R, increase four-time accuracy. adopt Japanese Lejing coder that has strong anti-jamming capability, displacement resolution 0.001mm.

Small deformation: Metal extensometers, parsing 0.001mm.

K. Safe equipment: the system would shut down if overload or over-trip

2. items can be tested in the Computer Servo Type Universal Testing Machine

Common items: ( display data and calculation )

● tensile stress ● tensile strength

● tensile strength ● rate of elongation at break

● fixed stress ● rate of stress at break

● stress strength ● tear strength

● the value of force at any point ●rate of elongation at any point

● pull-out strength ● force of adhesion and value of peak

3.Computer servo control material testing machine test curve